If you’re in the world of modular assembly, you’ve probably heard of the Minitec profile system. But how can this innovative system truly change the way things are built? Is it just another solution, or does it have the power to revolutionize the way we approach complex design and construction? Let’s break down what makes this system so special and how it can reshape the way modular projects are handled.

Enhanced Flexibility for Complex Design Configurations

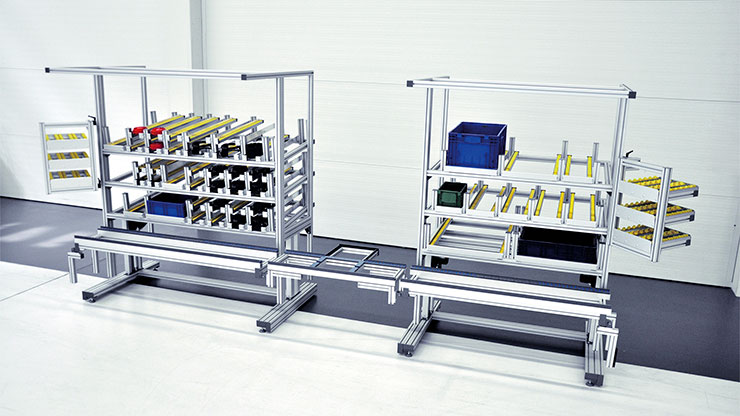

One of the standout features of the Minitec profile system is its incredible flexibility. Whether you’re working on a large-scale industrial project or a more intricate design, this system adapts to your needs. Its modular nature allows users to easily adjust, expand, or even redesign their configurations without hassle.

The system’s ability to accommodate complex configurations makes it ideal for projects where traditional solutions would struggle. Whether you’re designing custom machinery, workstations, or structural components, Minitec solutions provide a level of versatility that’s hard to match. This adaptability makes it a game-changer for industries that need to remain agile while meeting specific design requirements.

Precision Engineering for Seamless Modular Integration

Precision is key when dealing with modular systems, and the Minitec profile system delivers in this area. Each component is engineered to ensure that all parts fit together perfectly, creating a seamless and efficient assembly. The attention to detail in the Minitec profile system not only enhances the quality of the final product but also reduces the chance of errors during assembly.

The high level of precision engineering in Minitec solutions means that each modular component aligns accurately with the others. This leads to fewer adjustments during the assembly process and ensures that everything operates as intended. For industries where precision is non-negotiable, this system offers peace of mind.

Quick and Efficient Assembly for Shorter Project Timelines

Time is money, especially when it comes to industrial projects. The quicker a system can be assembled, the faster the project can move forward. With the Minitec profile system, assembly is quick and efficient. Thanks to its modular design and precision engineering, components can be easily put together without the need for specialized tools or labor.

The speed of assembly doesn’t compromise the quality of the build. In fact, by simplifying the process, the Minitec profile system allows teams to maintain high standards while still cutting down on project timelines. For businesses that need to meet tight deadlines, this efficiency is invaluable.

Increased Durability with High-Quality Aluminum Profiles

Durability is a major consideration in modular assembly, and the Minitec profile system excels in this area. Made from high-quality aluminum, these profiles are built to last. Aluminum offers a great balance between strength and weight, making it ideal for both heavy-duty and lightweight applications.

Not only are the aluminum profiles resistant to wear and tear, but they also stand up to harsh environments. Whether exposed to extreme temperatures, humidity, or heavy usage, Minitec solutions provide long-lasting reliability. This durability reduces the need for frequent repairs or replacements, saving businesses time and money in the long run.

Customizable Components for Tailored Industrial Solutions

One size rarely fits all in the industrial world, and that’s where Minitec really shines. The system offers a wide range of customizable components, allowing businesses to create solutions tailored to their specific needs. From size and shape to the functionality of the modular pieces, everything can be adjusted to suit your project.

This level of customization makes the Minitec profile system particularly attractive for industries with unique or evolving requirements. Whether it’s for assembly lines, machine frames, or laboratory equipment, Minitec solutions provide the flexibility to design exactly what you need without compromise.

Cost-Effective Production with Minimal Waste

Every business wants to keep costs down, and the Minitec profile system helps make that possible. Its modular nature reduces material waste during production, as each component is designed to fit together perfectly, minimizing offcuts and errors. The use of aluminum, which is both lightweight and durable, also reduces material and transportation costs.

In addition to reducing waste, the quick assembly process cuts down on labor costs, as fewer man-hours are needed to complete a project. For companies looking to maintain high standards without overspending, the Minitec profile system offers a cost-effective solution that doesn’t skimp on quality.